Advancements in Automotive Chassis Engineering

The automotive chassis, often considered the backbone of any vehicle, plays a pivotal role in defining its structural integrity, handling characteristics, and overall safety. Over the years, significant strides in engineering, materials science, and manufacturing processes have transformed this fundamental component. Modern chassis designs are far more sophisticated, integrating advanced technologies to meet evolving demands for performance, efficiency, and occupant protection in the diverse landscape of global mobility.

The Core Role of Chassis in Vehicle Design and Safety

The chassis serves as the foundational framework upon which all other vehicle components are mounted. Its primary functions include supporting the engine, transmission, body, and suspension systems, while also bearing the stresses from driving. Beyond structural support, the chassis is critical for occupant safety, absorbing and distributing impact forces during collisions. Modern automotive engineering focuses heavily on optimizing chassis design to enhance torsional rigidity and bending stiffness, which directly translates to improved handling, a more comfortable ride, and heightened responsiveness for the driver. This fundamental component is continuously refined to meet stringent safety regulations and consumer expectations for a secure and dynamic driving experience.

Materials Innovation for Enhanced Performance and Mobility

One of the most impactful areas of advancement in chassis engineering is the adoption of new materials. Traditional steel constructions are being augmented or replaced by lightweight yet strong alternatives like high-strength steel alloys, aluminum, and carbon fiber composites. These materials offer a significant reduction in vehicle weight without compromising structural integrity. A lighter chassis contributes directly to improved fuel efficiency in conventional vehicles and extends the range of electric cars. Furthermore, the tailored properties of these advanced materials allow engineers to design structures that deform predictably during impacts, further enhancing passenger safety. This innovation in materials science is crucial for the ongoing evolution of transport and mobility.

Adapting Chassis for Electric and Hybrid Vehicles

The rise of electric and hybrid vehicles has presented unique challenges and opportunities for chassis design. Unlike internal combustion engine vehicles, electric powertrains often require a ‘skateboard’ architecture, where the battery pack is integrated into the floor of the chassis. This approach offers benefits such as a low center of gravity, which improves stability and handling, and optimal weight distribution. Chassis engineering for electric vehicles must account for the substantial weight of battery packs while ensuring efficient packaging and thermal management. The design must also protect the battery from impact, making robust structural solutions paramount. This adaptation highlights how vehicle electrification is profoundly influencing fundamental automotive engineering principles.

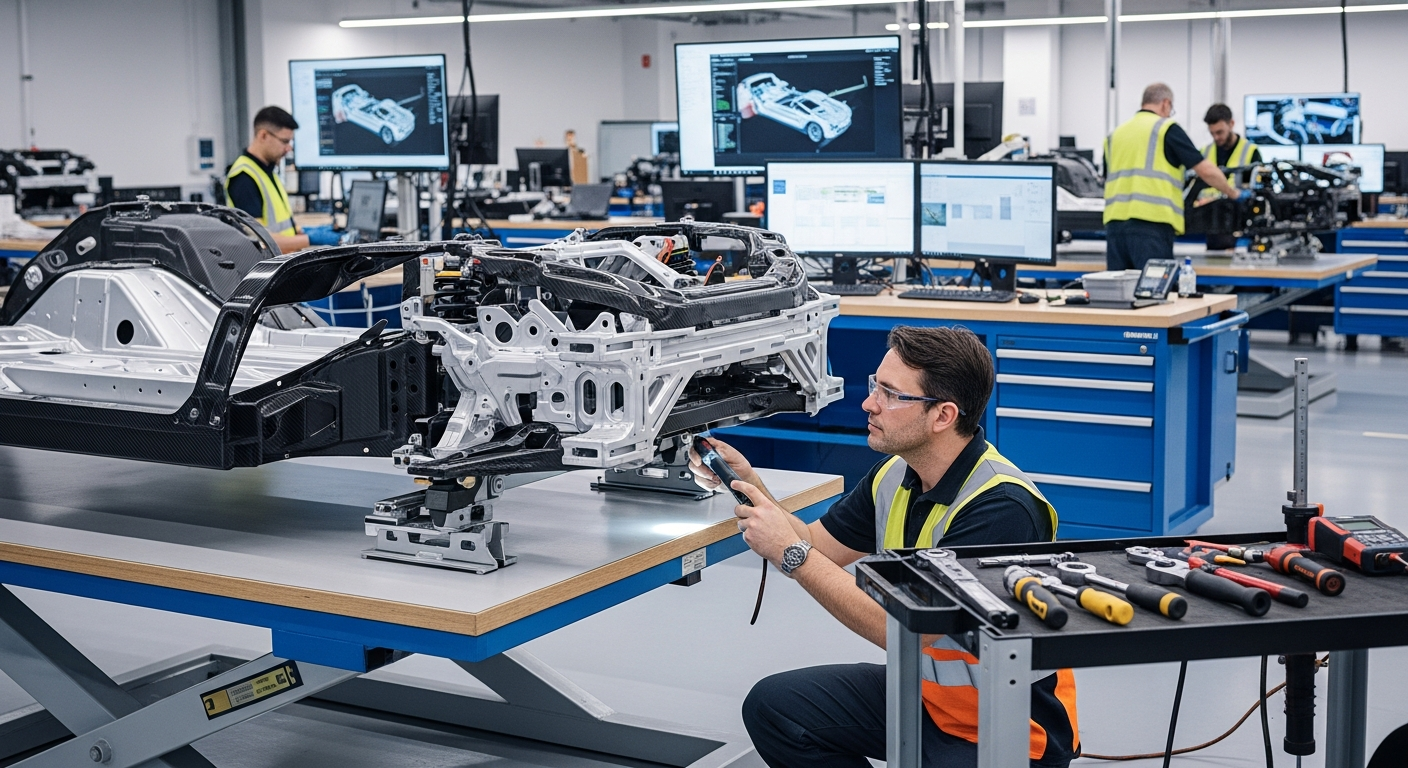

Advanced Manufacturing Techniques in Chassis Production

Modern manufacturing processes have revolutionized how chassis components are produced, leading to greater precision, efficiency, and design flexibility. Techniques such as advanced laser welding, friction stir welding, and structural adhesive bonding allow for the joining of dissimilar materials with superior strength and reduced weight. The use of hydroforming enables the creation of complex shapes from single pieces of metal, reducing the need for multiple welded parts and improving structural integrity. Furthermore, advancements in stamping and casting technologies, alongside the emergence of additive manufacturing (3D printing) for prototyping and specialized components, are pushing the boundaries of what is possible in chassis design and production. These technologies are vital for creating innovative and high-performance automotive structures.

Integrating Technology for Enhanced Driving Dynamics and Autonomous Systems

Contemporary chassis engineering goes beyond passive structural elements to integrate active technologies that enhance driving dynamics and support the development of autonomous vehicles. Active suspension systems, for instance, can dynamically adjust damping and ride height to optimize comfort and handling across varying road conditions. Steer-by-wire and brake-by-wire systems, which replace mechanical linkages with electronic controls, offer greater precision, quicker response times, and enable advanced driver-assistance features crucial for autonomous driving. These technological integrations allow the chassis to become an intelligent platform, contributing to improved safety, fuel efficiency, and a more intuitive driving experience. The future of urban and long-distance transport heavily relies on these sophisticated engineering advancements.

Cost Considerations in Advanced Chassis Engineering

The adoption of advanced materials and manufacturing processes in chassis engineering often involves higher initial costs compared to traditional methods. For instance, high-strength steels can be more expensive to produce and process, while aluminum and carbon fiber composites have significantly higher material costs. Specialized manufacturing equipment for advanced welding, bonding, and hydroforming also represents a substantial investment. These costs are typically offset by benefits such as improved fuel economy, enhanced safety ratings, and the potential for greater design flexibility and innovation, which can lead to long-term savings and market differentiation. While the exact figures vary widely depending on the vehicle segment and specific technologies employed, the automotive industry continuously seeks cost-effective ways to integrate these advancements, balancing performance gains with economic viability for consumers and manufacturers alike.

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

The Future Trajectory of Automotive Chassis Innovation

The trajectory of automotive chassis engineering points towards even greater integration of lightweight materials, intelligent systems, and modular designs. As vehicle electrification and autonomous driving capabilities become more prevalent, the chassis will evolve into a highly adaptable and interconnected platform. Future designs will likely prioritize further weight reduction, enhanced energy absorption capabilities, and greater flexibility to accommodate diverse powertrain configurations and digital technologies. The continuous push for improved safety, reduced emissions, and enhanced user experience will ensure that innovation in chassis engineering remains a critical driver for the entire automotive industry, shaping the future of individual and collective mobility.